Qaybaha alloy ee Titanium-cagaf-Qayb/Mashiinnada Ciidda Biraha/Mashiinnada Mashiinnada/Mashiinnada/ Qaybaha Matoorka ee Jirka Isku-buuqa

| Qalab | Aluminium: AL6061, Al6063, AL6082, AL7075, AL5052, AL2024 |

| Birta aan la taaban karin: SS201, SS301, SS303, SS304, SS316, SS430 iwm | |

| Steel: bir khafiif ah / bir kaarboon oo ay ku jiraan 1010, 1020, 1045, 1050, Q690 iwm | |

| Naxaasta: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 iwm. | |

| Copper: C11000, C12000, C12000, C17200, C72900, C36000 iwm. | |

| Habaynta | Germany Trumpf calaamad Laser cutter, mashiinka xiirashada CNC, mashiinka foorarsiga CNC, |

| (CNC) mashiinka shaabadda, Mashiinka Hyraulic, Mashiinka alxanka kala duwan, CNC xarunta mashiinka. | |

| Dusha sare | Aluminium: Anodization, Sandblast, cadayashada, polishing, Electro-plating iwm |

| Birta Aan Lahayn: Daliishada, Cadayashada, Baasabka, Bacaad-qarxinta, Electro-plating | |

| Birta: dahaadhka Zinc, dajinta nikkel, dahaadhay Chrome, daahan budo, rinjiyeynta iwm | |

| Naxaasta & naxaasta: cadayashada, suufka iwm | |

| Saxnaanta | + - 0.1mm |

| Codsiga | Jidka Tareenka, Baabuurka, Baabuurka, Caafimaadka, Mashiinnada, Qalabka, Elektarooniga, Korontada iwm |

Titanium waa nooc cusub oo bir ah.Waxqabadka titanium wuxuu la xiriiraa waxyaabaha wasakhda ah sida kaarboon, nitrogen, hydrogen iyo oxygen.Maaddada wasakhda ah ee titanium iodide saafi ah ayaa ka yar 0.1%, laakiin xooggeedu waa hooseeyaa iyo caaggu waa sarreeyaa. Waxyaabaha 99.5% titanium saafiga ah ee warshadaha waa sida soo socota: cufnaanta ρ = 4.5g / cm3, dhibic dhalaalaysa 1725 ℃, conductivity kaamerada λ = 15.24W / (mK), xoog adkaysi σb = 539MPa, elongation δ = 25%, hoos u qayb ψ = 25%, modules of barti E = 1.078 × 105MPa, adkaanta HB195.

Xoog sare

Cufnaanta ee daawaynta titanium guud ahaan waa qiyaastii 4.51g / cm3, kaliya 60% birta, iyo qaar ka mid ah Alloys titanium xoogga sare ka badan xoogga biraha qaab-dhismeedka Alloy badan.Sidaas darteed, xoogga gaarka ah (xoog / cufnaanta) ee alloy titanium aad u weyn. marka loo eego kuwa kale ee qalabka dhismaha ee birta ah, kuwaas oo soo saari kara qaybo leh awood sare oo unug ah, qallafsanaan wanaagsan iyo miisaan fudud. Qaybaha matoorka diyaaradaha, qalfoofka, maqaarka, xirmooyinka iyo qalabka soo degaya dhamaantood waxay isticmaalaan titanium alloy.

Xoogga kulaylka sare

Heerkulka isticmaalka waa dhowr boqol oo darajo oo ka sarreeya daawaha aluminium, weli wuxuu sii wadi karaa xoogga loo baahan yahay heerkulka dhexdhexaadka ah, wuxuu shaqeyn karaa waqti dheer heerkulka 450 ~ 500 ℃.Labadan nooc ee daawaynta titanium in 150 ℃ ~ 500 ℃ kala duwan ayaa weli ah xoog gaar ah oo aad u sarreeya, iyo daawaha aluminium at 150 ℃ xoog gaar ah hoos u dhacay si weyn. 200℃

Iska caabbinta wanaagsan ee daxalka

Iska caabbinta daxalka ee alloy titanium aad ayuu uga fiican yahay birta aan fiicnayn ee jawiga qoyan iyo biyaha badda , sulfuric acid, iwm. Laakiin iska caabbinta daxalka ee titanium si loo yareeyo oksijiinta iyo dhexdhexaadka chromium waa liidata.

Waxqabad heerkul hooseeya oo wanaagsan

Titanium Alloy waxay ilaalin kartaa sifooyinkeeda farsamo ee heerkulka hooseeya iyo kuwa hooseeya. qalab dhisme heerkul hooseeya.

Dhaqdhaqaaqa kiimikaad oo sarreeya

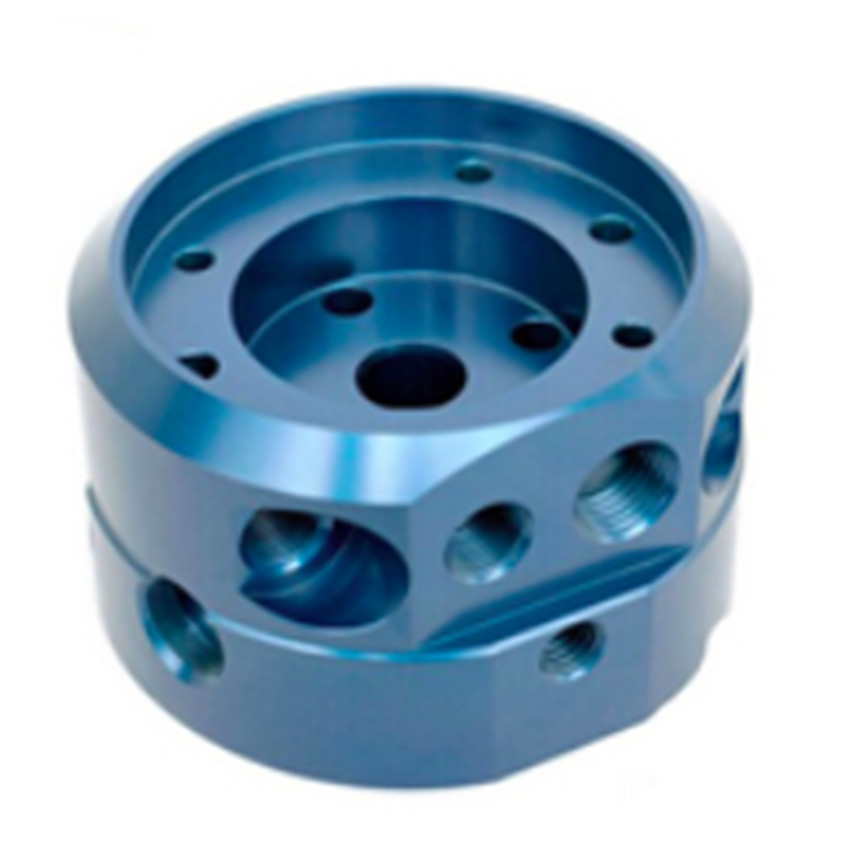

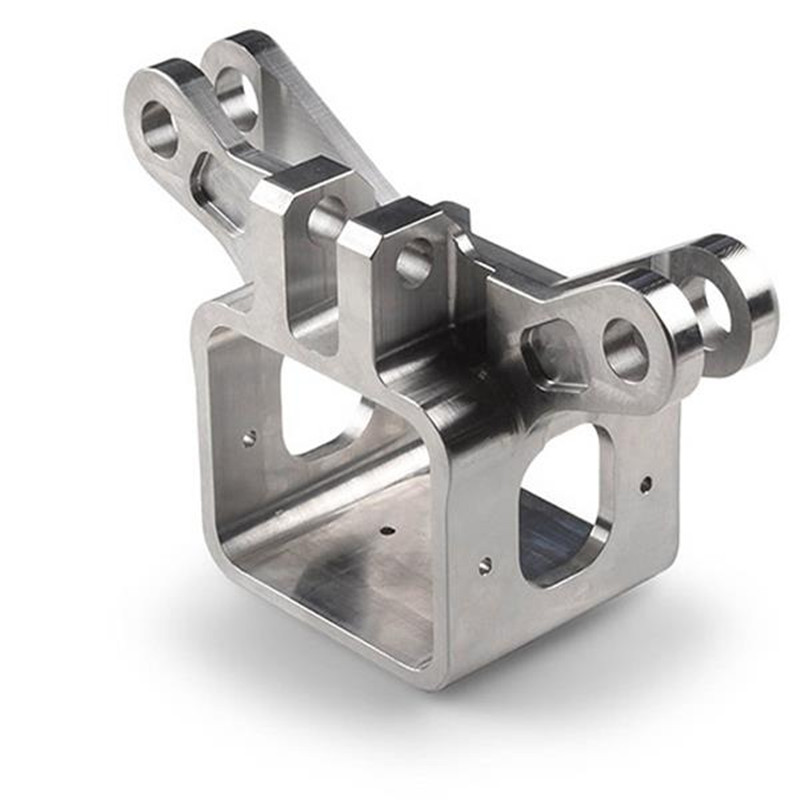

Alaabta Titanium

Alaabta Titanium

Titanium waxay leedahay falcelin kiimiko oo xoog leh oo leh O2, N2, H2, CO, CO2, uumiga biyaha, ammonia iyo gaasaska kale ee ku jira jawiga.Marka kaarboonku ka weyn yahay 0.2%, TiC adag ayaa la samayn doonaa alloy titanium.Marka Heerkulku waa sarreeyaa, lakabka dusha adag ee TiN waxaa la samayn doonaa isdhexgalka N. Marka heerkulku ka sarreeyo 600 ℃, titanium wuxuu nuugaa ogsijiinta wuxuuna sameeyaa lakab adag oo adag oo sarreeya. Sida content hydrogen-ka kor u kaco, lakabka jajaban ayaa noqon doona sidoo kale waxay sameeyaan.Qoto dheer ee lakabka sare ee adag iyo jilicsan ee ay soo saarto nuugista gaaska waxay gaari kartaa 0.1 ~ 0.15 mm, iyo heerka adkaanta waa 20% ~ 30% Kiimikada Titanium sidoo kale waa weyn, fududahay in la soo saaro adhesion oo leh jajab. dusha sare.

Laastikada kulaylka yar yar

Heerarka kulaylka ee titanium (λ = 15.24W / (m · K)) waxay ku saabsan tahay 1/4 ee nikkel, 1/5 ee birta, 1/14 ee aluminium, iyo kuleylka kuleylka ee titanium kala duwan Alloys wuxuu ku saabsan yahay 50% ka hooseeya kan titanium. The elastic modules of titanium alloy wuxuu ku saabsan yahay 1/2 ee birta, sidaas darteed qallafsanaantiisu waa mid liidata, fududahay in la beddelo, waa in aan laga samayn ul caato ah iyo qaybo dhuuban, jarida marka farsamaynta dusha sare ee dib-u-soo-celinta waa weyn tahay, oo ku saabsan 2 ~ 3 jeer oo birta ah, taas oo keentay khilaaf ba'an, dhejis, xirashada koollada dusha qalabka.